HISTORIC AMERICAN ENGINEERING RECORD

CHICAGO & NORTH WESTERN RAILWAY, KINZIE STREET BRIDGE[1![]() ]

]

HAER No. IL-142

| Location: | Spanning N. Branch of Chicago River, S. of Kinzie St., Chicago, Cook County, Illinois. |

| USGS Quadrangle: | Chicago Loop, Illinois (7.5-minute series). |

| UTM Coordinates: | 16/446985/4637360 |

| Dates of Construction: | 1907-1908. |

| Designers: | William H. Finley, Assistant Chief Engineer of the Chicago & North Western Railway (Chicago), substructure; Strauss Bascule & Concrete Bridge Co. (Chicago), superstructure. |

| Fabricator: | Toledo-Massillon Bridge Co. (Toledo, Ohio). |

| Builders: | Great Lakes Dredge & Dock Co. (Chicago), substructure; Kelly-Atkinson Construction Co. (Chicago), superstructure. |

| Present Owner: | Union Pacific Railroad (Omaha, Nebraska). |

| Present Use: | Railroad bridge. |

| Significance: | The Kinzie Street Bridge occupies the site of Chicago's first railroad bridge (1852), and also the nation's first all-steel railroad bridge (1879). The line served Wells Street Station and industries in the Near North Side, contributing much to that area's development. The present structure is an overhead-counterweight bascule bridge based on the patents of Joseph B. Strauss, and was the world's longest and heaviest bascule leaf at the time of its completion. This is a particularly unusual example of its type because certain elements foreshadow Strauss' subsequent development of a heel-trunnion design for long bascule spans. |

| Historian: | Justin M. Spivey, January 2001. |

| Project Description: | The Chicago Bridges Recording Project was sponsored during the summer of 1999 by HABS/HAER under the general direction of E. Blaine Cliver, Chief; the City of Chicago, Richard M. Daley, Mayor; the Chicago Department of Transportation, Thomas R. Walker, Commissioner, and S. L. Kaderbek, Chief Engineer, Bureau of Bridges and Transit. The field work, measured drawings, historical reports, and photographs were prepared under the direction of Eric N. DeLony, Chief of HAER. |

CHRONOLOGY

| 25 Oct. 1848 | Galena & Chicago Union Railroad (G&CU) begins operating trains from station on west bank of North Branch of Chicago River. |

| 1852 | G&CU extends line eastward, crossing North Branch of Chicago River on pontoon bridge to serve new Wells Street Station on east bank. |

| 1861 | G&CU extends line further eastward, to Ogden Slip and North Pier. |

| 1864 | Chicago & North Western Railway (C&NW) absorbs G&CU. |

| 1879 | C&NW constructs a swing bridge, among the first all-steel spans in the U.S., at Kinzie Street crossing. |

| 1897 | U.S. Army Corps of Engineers survey of Chicago River notes that Kinzie Street Bridge is an obstacle to navigation. |

| 14 Mar. 1898 | Another swing bridge, replacing 1879 span, opens to traffic. |

| Circa 1905 | U.S. Secretary of War orders removal of Kinzie Street Bridge. |

| 11 Oct. 1906 | U.S. Secretary of War approves new C&NW bridge at Kinzie Street. |

| 17 Dec. 1906 | City of Chicago approves new C&NW passenger terminal on west bank. |

| 26 Dec. 1907 | Construction begins on new Strauss overhead-counterweight bascule span at Kinzie Street. |

| 19 Sep. 1908 | C&NW places new Kinzie Street Bridge in service. |

| 4 June 1911 | First train arrives at new C&NW passenger terminal on west bank; Kinzie Street Bridge relegated to freight traffic. |

| 1995 | Union Pacific Railroad (UP) absorbs C&NW. |

Introduction

If there is one continuous thread in the history of Chicago's Kinzie Street railroad bridge,

it is William B. Ogden (1805-1877), an archetypical nineteenth-century "booster" and a recurring

figure in the city's early history. Indeed, Ogden seems almost omnipresent in Chicago after his

arrival in June 1835: selling real estate, contracting on the Illinois & Michigan Canal, presiding

over the first successful railroad—not to mention serving as the city's first mayor. His ceaseless

promotion of "public improvements" undoubtedly raised land values (among his own holdings if

not elsewhere). One biography endows him with earth-moving omnipotence: "He made many

rough places smooth, and the crooked ways straight."[2![]() ]

Beyond city limits, Ogden's grandest

achievements were in developing the transportation arteries that helped fuel Chicago's

spectacular growth during the mid-nineteenth century.

]

Beyond city limits, Ogden's grandest

achievements were in developing the transportation arteries that helped fuel Chicago's

spectacular growth during the mid-nineteenth century.

Interestingly, Ogden was involved in the early stages of all three railroads that have

crossed the North Branch of the Chicago River near Kinzie Street. He seemed to specialize in

jump-starting projects that had stalled for lack of investment. After helping to bring into being

the long-envisioned canal linking the Lake Michigan and Mississippi River watersheds, Ogden

turned to promoting railroads. His first such project was a railroad that had been chartered in

1836 to connect Chicago with the Mississippi River through the lead-mining region around

Galena. According to railroad historian H. Roger Grant, the Galena & Chicago Union Railroad

(G&CU) "seemed destined to remain a 'paper' project" until Ogden became its president in the

late 1840s.[3![]() ]

Under Ogden's leadership, the railroad ran its first train in 1848. Although it never

reached Galena, the G&CU did become a successful link between Chicago and its western

hinterlands. The G&CU was acquired in 1864 by another Ogden-promoted project, the Chicago

& North Western Railway (C&NW). The C&NW's predecessor company had declared

bankruptcy in 1859 and was reorganized with Ogden in charge. He brought success to the

C&NW, which soon became one of the country's largest and most prosperous.[4

]

Under Ogden's leadership, the railroad ran its first train in 1848. Although it never

reached Galena, the G&CU did become a successful link between Chicago and its western

hinterlands. The G&CU was acquired in 1864 by another Ogden-promoted project, the Chicago

& North Western Railway (C&NW). The C&NW's predecessor company had declared

bankruptcy in 1859 and was reorganized with Ogden in charge. He brought success to the

C&NW, which soon became one of the country's largest and most prosperous.[4![]() ]

A third and final

consolidation occurred well after Ogden's lifetime, but nonetheless bears the mark of his

influence. The Union Pacific Railroad (UP), which acquired the C&NW during a time of late

twentieth-century railroad mergers, can attribute its early success to Ogden's presidency during

1862 and 1863. According to Grant, "his presence gave considerable prestige to the project."[5

]

A third and final

consolidation occurred well after Ogden's lifetime, but nonetheless bears the mark of his

influence. The Union Pacific Railroad (UP), which acquired the C&NW during a time of late

twentieth-century railroad mergers, can attribute its early success to Ogden's presidency during

1862 and 1863. According to Grant, "his presence gave considerable prestige to the project."[5![]() ]

When the UP opened to through traffic in mid-1868, Chicago had a continuous railroad

connection between Kinzie Street and the Pacific coast, with the C&NW carrying traffic as far as

Omaha. Chicago, a small town with 1,500 residents upon Ogden's arrival, had become a city of

200,000 and the rail hub of the North American continent.[6

]

When the UP opened to through traffic in mid-1868, Chicago had a continuous railroad

connection between Kinzie Street and the Pacific coast, with the C&NW carrying traffic as far as

Omaha. Chicago, a small town with 1,500 residents upon Ogden's arrival, had become a city of

200,000 and the rail hub of the North American continent.[6![]() ]

]

Although the G&CU and its successors are best known for their westward expansion, the

Kinzie Street Bridge is the result of a small but significant eastward extension. When the first

train ran on the G&CU in 1848, it departed from a station at Kinzie Street on the west bank of

the Chicago River's North Branch. Although the heart of the city was on the east bank of the

South Branch, the omission of a railroad bridge was hardly fatal at that time. Federally

sponsored improvements to the Chicago River's mouth allowed lake-going ships to enter the

river and connect with the railroad terminal. Moreover, some of Chicago's industries, the lumber

trade in particular, were already moving to less expensive land on the west bank.[7![]() ]

At any rate,

the fledgling G&CU may not have been able to afford the expense of bridging the North Branch.

The railroad's financial situation soon improved, however, and in 1852 trains began crossing a

new pontoon bridge to a station at Wells Street. Although closer than the old Kinzie Street

Station, the Wells Street Station was still separated from the central business district by the

Chicago River's Main Branch. Nonetheless, the railroad's passenger service became highly

successful, requiring several expansions of the station during the nineteenth century.[8

]

At any rate,

the fledgling G&CU may not have been able to afford the expense of bridging the North Branch.

The railroad's financial situation soon improved, however, and in 1852 trains began crossing a

new pontoon bridge to a station at Wells Street. Although closer than the old Kinzie Street

Station, the Wells Street Station was still separated from the central business district by the

Chicago River's Main Branch. Nonetheless, the railroad's passenger service became highly

successful, requiring several expansions of the station during the nineteenth century.[8![]() ]

]

The Kinzie Street Bridge also carried freight trains, fueling development on the Near

North Side. A small industrial district began developing along the G&CU's tracks east of the

North Branch, including warehouses and grain elevators constructed by the railroad in 1854.[9![]() ]

As

other railroads entered Chicago, the G&CU built tracks for interchange traffic and spurs to serve

industry. In 1861, the railroad's annual report mentioned "new tracks in Chicago ... to

accommodate the business of certain lumber yards in the city."[10

]

As

other railroads entered Chicago, the G&CU built tracks for interchange traffic and spurs to serve

industry. In 1861, the railroad's annual report mentioned "new tracks in Chicago ... to

accommodate the business of certain lumber yards in the city."[10![]() ]

The new tracks included another

eastward extension of the main line, serving Ogden Slip and terminating at a pier reaching into

Lake Michigan (a predecessor of the current Navy Pier). The Illinois Central Railroad added a

bridge across the Chicago River's mouth in the late nineteenth century, but when this was

demolished in 1904, the C&NW's Kinzie Street Bridge became once again the only railroad

connection to the Near North Side.[11

]

The new tracks included another

eastward extension of the main line, serving Ogden Slip and terminating at a pier reaching into

Lake Michigan (a predecessor of the current Navy Pier). The Illinois Central Railroad added a

bridge across the Chicago River's mouth in the late nineteenth century, but when this was

demolished in 1904, the C&NW's Kinzie Street Bridge became once again the only railroad

connection to the Near North Side.[11![]() ]

By that time, the heavy demands placed on the Kinzie

Street Bridge led the C&NW to re-design its entire Chicago terminal. A history of the Kinzie

Street crossing will serve as an introduction to the current bridge, completed in 1908.

]

By that time, the heavy demands placed on the Kinzie

Street Bridge led the C&NW to re-design its entire Chicago terminal. A history of the Kinzie

Street crossing will serve as an introduction to the current bridge, completed in 1908.

The Kinzie Street Crossing

The Kinzie Street crossing has been the site of many firsts. As Chicago expanded beyond

the peninsula occupied by Fort Dearborn, the city constructed bridges over the Chicago River and

its branches. According to the Chicago Department of Public Works, the first North Branch

crossing was a pedestrian bridge constructed in 1832, "about where the present C. and N. W.

Railway bridge is located, near Kinzie street."[12![]() ]

Two decades later, the G&CU—Chicago's first

railroad—crossed the North Branch on Chicago's first railroad bridge. Subsequent

replacements of this structure included one of the nation's first all-steel railroad bridges in 1879,

and the world's longest and heaviest bascule leaf at the time of its completion in 1908.

]

Two decades later, the G&CU—Chicago's first

railroad—crossed the North Branch on Chicago's first railroad bridge. Subsequent

replacements of this structure included one of the nation's first all-steel railroad bridges in 1879,

and the world's longest and heaviest bascule leaf at the time of its completion in 1908.

In its annual report of 1851, the G&CU's chief engineer reported that construction of a

"Chicago extension" was in progress, including a drawbridge estimated to cost $20,000.[13![]() ]

The

line would cross the North Branch of the Chicago River to serve a new Wells Street Station

closer to downtown. According to one company history, superintendent Jenks D. Perkins

designed a "pontoon or floating bridge," completed in 1852.[14

]

The

line would cross the North Branch of the Chicago River to serve a new Wells Street Station

closer to downtown. According to one company history, superintendent Jenks D. Perkins

designed a "pontoon or floating bridge," completed in 1852.[14![]() ]

This structure was not long-lived,

however, if an 1857 map is to be believed. Cartographer James T. Palmatary's pictorial view of

Chicago shows what is unmistakably a swing bridge at the Kinzie Street crossing.[15

]

This structure was not long-lived,

however, if an 1857 map is to be believed. Cartographer James T. Palmatary's pictorial view of

Chicago shows what is unmistakably a swing bridge at the Kinzie Street crossing.[15![]() ]

Like

contemporary bridges throughout Chicago and the nation, this swing span would have had

wooden structural members, with iron used only for rails, fasteners, and perhaps tension rods.

]

Like

contemporary bridges throughout Chicago and the nation, this swing span would have had

wooden structural members, with iron used only for rails, fasteners, and perhaps tension rods.

Metal parts found greater use in the next railroad bridge at Kinzie Street, constructed by

the C&NW in the spring of 1879. By that time, companies such as Phoenix Iron of Phoenixville,

Pennsylvania, had developed standardized wrought-iron members for use in bridge and building

structures. But the Kinzie Street bridge's members consisted exclusively of a modified Bessemer

steel rather than wrought iron, making it among the first all-steel railroad bridges in the U.S.

(along with the Glasgow Bridge across the Missouri River, built concurrently). Because wrought

iron derives its strength from repeated heating and working, a process which was never entirely

mechanized, mass production of metal structures demanded a less labor-intensive material.

Henry Bessemer's process of converting iron to steel, developed in the mid-1850s, answered this

need but produced a metal prone to brittle fracture under impact loading. As historian Thomas J.

Misa explained in A Nation of Steel, his study of the American steel-making industry, Bessemer

steel filled an enormous demand for railroad rails, but attempts to use it in railroad bridges were

"experimental" and "unsatisfactory."[16![]() ]

Particular results of the C&NW's experiment at Kinzie

Street were reported to the Western Society of Engineers by Assistant Chief Engineer William H.

Finley. Speaking in 1899 after the bridge was dismantled, Finley described numerous incidents

of brittle cracking, and the difficulty of making repairs without causing even more cracks to

appear. The metal used in the bridge was a Bessemer steel, modified by the Hay process of

adding a special slag during smelting, and rolled at Carnegie Steel's Edgar Thompson works for

the American Bridge Company. Instead of directly condemning the material, Finley presented a

chemical analysis showing relatively high amounts of phosphorous and sulfur, both of which

make steel brittle.[17

]

Particular results of the C&NW's experiment at Kinzie

Street were reported to the Western Society of Engineers by Assistant Chief Engineer William H.

Finley. Speaking in 1899 after the bridge was dismantled, Finley described numerous incidents

of brittle cracking, and the difficulty of making repairs without causing even more cracks to

appear. The metal used in the bridge was a Bessemer steel, modified by the Hay process of

adding a special slag during smelting, and rolled at Carnegie Steel's Edgar Thompson works for

the American Bridge Company. Instead of directly condemning the material, Finley presented a

chemical analysis showing relatively high amounts of phosphorous and sulfur, both of which

make steel brittle.[17![]() ]

It was not until the advent of the basic open-hearth process in the late 1880s

that U.S. steel-makers could remove these undesirable elements to mass-produce reliable

structural steel.

]

It was not until the advent of the basic open-hearth process in the late 1880s

that U.S. steel-makers could remove these undesirable elements to mass-produce reliable

structural steel.

Because of its metallurgical inadequacy, the 1879 bridge was deemed obsolete after just

eighteen years of service. Its replacement, fabricated by the Lassig Bridge & Iron Works and

erected in March 1898, incorporated several unusual features that merit brief description here.[18![]() ]

The movable span was a triple-intersection riveted lattice truss, a type which has always been

more popular in Europe than in America. In defending his choice of a riveted lattice design,

Finley cited the greater structural redundancy which would help it to survive collisions with

boats, evidently a common occurrence on Chicago's crowded rivers.[19

]

The movable span was a triple-intersection riveted lattice truss, a type which has always been

more popular in Europe than in America. In defending his choice of a riveted lattice design,

Finley cited the greater structural redundancy which would help it to survive collisions with

boats, evidently a common occurrence on Chicago's crowded rivers.[19![]() ]

More unusual was the

pivot point, located under the midpoint of the southern truss rather than in the center of the span.

Furthermore, the span incorporated a special double-rack system, which allowed it to rotate 75.0

degrees over a roller nest covering only 37.5 degrees of arc.[20

]

More unusual was the

pivot point, located under the midpoint of the southern truss rather than in the center of the span.

Furthermore, the span incorporated a special double-rack system, which allowed it to rotate 75.0

degrees over a roller nest covering only 37.5 degrees of arc.[20![]() ]

Finley had improved upon a

similar system installed on a nearby Chicago, Milwaukee & St. Paul Railway (Milwaukee Road)

bridge. The Milwaukee Road then incorporated Finley's improvements into another bridge near

Cortland Street the following year, demonstrating the sharing of information that occurred during

the era of in-house swing bridge design.[21

]

Finley had improved upon a

similar system installed on a nearby Chicago, Milwaukee & St. Paul Railway (Milwaukee Road)

bridge. The Milwaukee Road then incorporated Finley's improvements into another bridge near

Cortland Street the following year, demonstrating the sharing of information that occurred during

the era of in-house swing bridge design.[21![]() ]

With the turn of the twentieth century, however, this

era drew to a close and patented designs began to supersede swing bridges in Chicago. It is an

interesting coincidence that Joseph B. Strauss, an engineer at Lassig Bridge & Iron Works during

the C&NW's bridge replacement in 1898, went on to develop the proprietary bascule form that

replaced the Kinzie Street Bridge again a decade later.

]

With the turn of the twentieth century, however, this

era drew to a close and patented designs began to supersede swing bridges in Chicago. It is an

interesting coincidence that Joseph B. Strauss, an engineer at Lassig Bridge & Iron Works during

the C&NW's bridge replacement in 1898, went on to develop the proprietary bascule form that

replaced the Kinzie Street Bridge again a decade later.

A New Station, a New Bridge

The Wells Street Station's limited capacity became painfully evident by 1901, prompting

C&NW President Marvin Hughitt to consider a total reconfiguration of the railroad's Chicago

terminal.[22![]() ]

Although the Kinzie Street Bridge did limit the number of trains entering and leaving,

the station itself was constrained by a small site with no possibility of expansion.[23

]

Although the Kinzie Street Bridge did limit the number of trains entering and leaving,

the station itself was constrained by a small site with no possibility of expansion.[23![]() ]

Furthermore,

the Main Branch of the Chicago River stood between the station and the Loop. Moving the

station into the Loop was out of the question, but if the station could be located on the west bank

of the South Branch, it would be no further away while eliminating the need for passenger trains

to cross a bridge. In 1905, consulting engineer John F. Wallace proposed a new, much larger

station fronting on Madison Street between Canal and Clinton streets and stretching for three

blocks to the north. Tracks would approach the station on elevated viaducts, crossing over city

streets and several complicated rail junctions. The viaducts would connect with existing elevated

tracks west of Ashland Avenue and north of Chicago Avenue, which had been raised during the

1890s in response to city ordinances demanding the elimination of at-grade railroad crossings.[24

]

Furthermore,

the Main Branch of the Chicago River stood between the station and the Loop. Moving the

station into the Loop was out of the question, but if the station could be located on the west bank

of the South Branch, it would be no further away while eliminating the need for passenger trains

to cross a bridge. In 1905, consulting engineer John F. Wallace proposed a new, much larger

station fronting on Madison Street between Canal and Clinton streets and stretching for three

blocks to the north. Tracks would approach the station on elevated viaducts, crossing over city

streets and several complicated rail junctions. The viaducts would connect with existing elevated

tracks west of Ashland Avenue and north of Chicago Avenue, which had been raised during the

1890s in response to city ordinances demanding the elimination of at-grade railroad crossings.[24![]() ]

The terminal building on Madison Street, designed by Chicago architects Charles S. Frost and

Alfred H. Granger, was estimated to handle five times as many passengers as the old Wells Street

Station.[25

]

The terminal building on Madison Street, designed by Chicago architects Charles S. Frost and

Alfred H. Granger, was estimated to handle five times as many passengers as the old Wells Street

Station.[25![]() ]

After the new terminal opened, the C&NW would continue to use the Kinzie Street

Bridge to serve freight customers on the Near North Side, for which it was perfectly adequate.

Ground had yet to be broken on the station, however, when the railroad received a federal

mandate for the bridge's removal. Construction of a replacement span occurred in 1907 and

1908, while the old Wells Street Station was still handling its full load of passenger traffic.

]

After the new terminal opened, the C&NW would continue to use the Kinzie Street

Bridge to serve freight customers on the Near North Side, for which it was perfectly adequate.

Ground had yet to be broken on the station, however, when the railroad received a federal

mandate for the bridge's removal. Construction of a replacement span occurred in 1907 and

1908, while the old Wells Street Station was still handling its full load of passenger traffic.

Demands for the bridge's replacement came from those Chicago industries dependent on

river trade, which plied the city's waterways in ever-larger craft. As stated in an 1897 analysis of

obstructions in the Chicago River, "The dimensions of the river some thirty years ago were

ample for the commerce and traffic of that time.... Almost everything in the city [has] been 'kept

up with the times'—except the river."[26![]() ]

One diagram showed how three bridges at Kinzie

Street—the city-owned span carrying Kinzie Street itself, the C&NW bridge to the south, and

the Milwaukee Road bridge to the north—prevented the latest 432-foot ore boats from entering

the North Branch.[27

]

One diagram showed how three bridges at Kinzie

Street—the city-owned span carrying Kinzie Street itself, the C&NW bridge to the south, and

the Milwaukee Road bridge to the north—prevented the latest 432-foot ore boats from entering

the North Branch.[27![]() ]

The report, presented to the Western Society of Engineers in June 1898,

carried the weight of more than opinion. The speaker was G. A. M. Liljencrantz of the Army

Corps of Engineers' Chicago District, an arm of the U.S. War Department which had recently

become the powerful federal ally of Chicago industries shipping on the river.

]

The report, presented to the Western Society of Engineers in June 1898,

carried the weight of more than opinion. The speaker was G. A. M. Liljencrantz of the Army

Corps of Engineers' Chicago District, an arm of the U.S. War Department which had recently

become the powerful federal ally of Chicago industries shipping on the river.

The Army Corps' role in Chicago River navigation increased throughout the nineteenth

century. Although the Army began improving the Chicago River in 1833, when soldiers at Fort

Dearborn first attempted to straighten the river where it entered Lake Michigan, it did not use

federal appropriations for improvements beyond the river's mouth until 1896.[28![]() ]

During this time

the agency did exert some control over the river, although one annual report hints that the

Chicago District had trouble enforcing a "mandate" regarding the city's Canal Street Bridge and

laws against dumping in the river.[29

]

During this time

the agency did exert some control over the river, although one annual report hints that the

Chicago District had trouble enforcing a "mandate" regarding the city's Canal Street Bridge and

laws against dumping in the river.[29![]() ]

Toward the century's end, however, declining river trade

highlighted the Chicago River's problems. The district engineer's recommendations against

swing bridges with mid-channel piers appear to have effectively prevented their construction

after 1890.[30

]

Toward the century's end, however, declining river trade

highlighted the Chicago River's problems. The district engineer's recommendations against

swing bridges with mid-channel piers appear to have effectively prevented their construction

after 1890.[30![]() ]

The River and Harbor Act of 1899 gave the Secretary of War authority to order

bridges removed, and imposed his approval as a necessary step in constructing bridges over

navigable waterways.[31

]

The River and Harbor Act of 1899 gave the Secretary of War authority to order

bridges removed, and imposed his approval as a necessary step in constructing bridges over

navigable waterways.[31![]() ]

The stage was set for the Army Corps to clear swing bridges from the

river.

]

The stage was set for the Army Corps to clear swing bridges from the

river.

The order to remove the three Kinzie Street bridges came shortly thereafter. Echoing

Liljencrantz's survey, the Army Corps' 1900 annual report complained that "the North Branch is

throttled near the junction at Kinzie street by three obstructive bridges." Further justifying its

position that these bridges should be removed, the District added, "The improvement of the

North Branch of the river is simple and may readily be made for the largest vessels.... The

tendency of commerce is already in the direction of the North Branch, and ... it may continue to

develop in that direction."[32![]() ]

Annual reports list bridge removal hearings on a sporadic basis, so

the exact date of the Secretary of War's order could not be determined. Replacement plans were

approved on 11 October 1906, however, with the city-owned and C&NW bridges considered

together because of their proximity.[33

]

Annual reports list bridge removal hearings on a sporadic basis, so

the exact date of the Secretary of War's order could not be determined. Replacement plans were

approved on 11 October 1906, however, with the city-owned and C&NW bridges considered

together because of their proximity.[33![]() ]

]

When planning the Kinzie Street Bridge replacement in 1906, the C&NW's choice was

more or less limited to the bascule type of bridge, where the span rotates about a horizontal axis.

Neither a vertical-axis swing bridge nor a horizontally translating span would fit on the small

site. Although J. A. L. Waddell had demonstrated his vertical-lift bridge on Chicago's South

Halsted Street in 1893, no railroad was daring enough to use it until 1909.[34![]() ]

A few folding spans

had been constructed in Chicago and elsewhere, but these lacked the rigidity needed for railroad

traffic. Waddell led the charge to condemn the "jack-knife" type as "a freak design."[35

]

A few folding spans

had been constructed in Chicago and elsewhere, but these lacked the rigidity needed for railroad

traffic. Waddell led the charge to condemn the "jack-knife" type as "a freak design."[35![]() ]

After

these choices had been eliminated, the bascule type was the only realistic option that remained.

The city of Chicago had developed its own bascule design, which was used on the Kinzie Street

roadway bridge.[36

]

After

these choices had been eliminated, the bascule type was the only realistic option that remained.

The city of Chicago had developed its own bascule design, which was used on the Kinzie Street

roadway bridge.[36![]() ]

The city's design was unavailable to the C&NW, and probably could not have

been adapted to meet the railroad's needs anyway. Lacking the experience and resources to

develop a single-leaf bascule bridge design in-house, the C&NW was left to choose among a

number of patented forms. According to Finely, the railroad contracted with the Strauss Bascule

& Concrete Bridge Company "after a careful comparison of the different types of bascule

bridges."[37

]

The city's design was unavailable to the C&NW, and probably could not have

been adapted to meet the railroad's needs anyway. Lacking the experience and resources to

develop a single-leaf bascule bridge design in-house, the C&NW was left to choose among a

number of patented forms. According to Finely, the railroad contracted with the Strauss Bascule

& Concrete Bridge Company "after a careful comparison of the different types of bascule

bridges."[37![]() ]

This decision was based on certain functional and economic advantages unique to the

Strauss type, to be discussed in detail below.

]

This decision was based on certain functional and economic advantages unique to the

Strauss type, to be discussed in detail below.

Early proposals for the Kinzie Street Bridge replacement show a scheme somewhat

different from the one actually built, reflecting some uncertainty in planning the terminal

reconfiguration. While the railroad began to acquire land for the new station and approaches in

1906, it had yet to receive the city's approval for the project. In order to cover the contingency

that the new station could not be built, the C&NW obtained a War Department permit to build

two double-track bascule bridges at Kinzie Street.[38![]() ]

While this would not provide the same

capacity as the proposed new station, it would increase the number of trains able to enter and

leave the old Wells Street Station in case the latter had to be kept in service. The four-track idea

persisted even after December 1906, when the City Council passed an ordinance authorizing the

new station. In September 1908, two months before work began on the new station, Engineering

News reported that the double-track bascule bridge just completed would be the first of two

parallel spans.[39

]

While this would not provide the same

capacity as the proposed new station, it would increase the number of trains able to enter and

leave the old Wells Street Station in case the latter had to be kept in service. The four-track idea

persisted even after December 1906, when the City Council passed an ordinance authorizing the

new station. In September 1908, two months before work began on the new station, Engineering

News reported that the double-track bascule bridge just completed would be the first of two

parallel spans.[39![]() ]

The C&NW ultimately decided against building the twin span, evidently

deeming it wasteful to improve the soon-to-be-abandoned Wells Street Station.[40

]

The C&NW ultimately decided against building the twin span, evidently

deeming it wasteful to improve the soon-to-be-abandoned Wells Street Station.[40![]() ]

Passenger

traffic shifted to the new station in June 1911, leaving the Kinzie Street Bridge's two tracks to

carry only freight traffic.

]

Passenger

traffic shifted to the new station in June 1911, leaving the Kinzie Street Bridge's two tracks to

carry only freight traffic.

Design and Construction: Substructure

Building the Kinzie Street Bridge's complex foundations, from December 1907 to May 1908, constituted a majority of the nine-month construction process. Assistant Chief Engineer Finley, while careful to credit his superiors, implied that he was the project's primary decision-maker in the articles that he wrote for engineering periodicals. He can be credited with designing the bridge's substructure, to which Chief Engineer E. C. Carter merely gave his approval. While the foundation plans were developed in-house, certain parameters were necessarily dictated by the superstructure design, which was contracted out to the Strauss Bascule & Concrete Bridge Company. The C&NW's use of a consulting engineer reflected a growing trend among American railroads in the early twentieth century, when in-house engineering staff could no longer keep up with the increasingly complex demands placed on movable bridges. Strauss' company and its proprietary bascule bridge design are discussed in separate sections below.

The Kinzie Street Bridge consists of two spans—a plate-girder span 25'-10" long on the

west approach and the 170'-0" bascule span—supported by three piers. The western abutment is

a 12'-0" by 35'-0" pier, skewed 15 degrees, on wooden piles driven 60'-0" below mean water

level. The intermediate pier, on which the bascule leaf rests in its closed position, measures

12'-0" by 41'-6", and is likewise skewed and pile-supported. By far the largest pier is the eastern

abutment, which carries the entire weight of the span and its counterweight in the open position.

This was also the most difficult part to construct because, unlike the other two piers, the eastern

abutment is carried by steel-lined concrete shafts driven to rock.[41![]() ]

Six shafts, each 10'-0" in

diameter and 65'-0" long, support a concrete-filled caisson. The caisson forms part of a large

block of concrete, which continues upward for another 62'-0-5/8" to the base-of-rail level. This

block is rectangular in plan, measuring 41'-8" by 49'-8", with the longer dimension parallel to the

tracks. It is equipped with small cantilevered wings to support struts bracing the tower under the

main trunnions.

]

Six shafts, each 10'-0" in

diameter and 65'-0" long, support a concrete-filled caisson. The caisson forms part of a large

block of concrete, which continues upward for another 62'-0-5/8" to the base-of-rail level. This

block is rectangular in plan, measuring 41'-8" by 49'-8", with the longer dimension parallel to the

tracks. It is equipped with small cantilevered wings to support struts bracing the tower under the

main trunnions.

Because the Wells Street Station had to remain open during construction, the railroad

took unusual steps to maintain traffic over the Kinzie Street Bridge. Early replacement plans

show the reverse of the as-built configuration, with the largest pier on the west shore, where it

could be constructed without interfering with the existing swing bridge. Finley noted that plans

were changed because it was less risky to sink the caisson in the east channel, which was not

usually used for navigation.[42![]() ]

On the other hand, the east channel site was obstructed by the

swing bridge whenever it opened, which was then thirty or forty times a day. To clear the way

for foundation work, the railroad cut off one arm of the swing bridge and replaced it with an

overhead counterweight on 1 September 1907. Just enough structure remained to support steel

boxes filled with pig iron, effectively converting the span into a "bobtail" swing bridge.

]

On the other hand, the east channel site was obstructed by the

swing bridge whenever it opened, which was then thirty or forty times a day. To clear the way

for foundation work, the railroad cut off one arm of the swing bridge and replaced it with an

overhead counterweight on 1 September 1907. Just enough structure remained to support steel

boxes filled with pig iron, effectively converting the span into a "bobtail" swing bridge.

Meanwhile, the Great Lakes Dredge & Dock Company was constructing the caisson for

the eastern abutment pier. The company's successful bid on the substructure contract was no

doubt aided by the proximity of its Chicago plant, located on Goose Island, about a mile

upstream from the bridge. Photographs of the Kinzie Street Bridge's foundations appear in a

1912 company brochure, which describes the company's work as "heavy foundations,

breakwaters, tunnels, docks, piers, lighthouses, bridges, and in fact, practically all branches of

work employing marine methods." During its twenty-two years of operation to date, the

company had purchased other engineering and contracting firms, resulting in "a Company

operating in practically every harbor and river tributary to the Great Lakes," i.e., Chicago,

Duluth, Cleveland, Buffalo, Sault Ste. Marie, and Amherstburg, Ontario.[43![]() ]

The company also

maintained a Boston office at that time, indicating a desire to expand onto the Atlantic coast.

]

The company also

maintained a Boston office at that time, indicating a desire to expand onto the Atlantic coast.

Despite the brochure's promotional intent, the photographs and their captions contain

significant data and dimensions, along with rare glimpses inside an early twentieth-century

pneumatic caisson. The heavy timber caisson left the Goose Island yard on 23 November 1907,

and reached the Kinzie Street site on 26 December.[44![]() ]

Photographs of the caisson during

excavation show air-locks for workers and materials (the latter is identified as a "Moran Material

Lock" in one caption), and even a view inside the working chamber. The caisson's interior

measured 41'-0" by 51'-0" in plan, and was lit by electric lighting during excavation.[45

]

Photographs of the caisson during

excavation show air-locks for workers and materials (the latter is identified as a "Moran Material

Lock" in one caption), and even a view inside the working chamber. The caisson's interior

measured 41'-0" by 51'-0" in plan, and was lit by electric lighting during excavation.[45![]() ]

Workers

removed soil from within the caisson, allowing it to gradually descend until it came to rest at

50'-10" below the river's surface on 21 February 1908. At that point, a concrete mat was poured

to seal the floor of the caisson, and work on the cylindrical shafts began. The first shaft reached

bedrock on 9 March, and all had been filled with concrete by 3 April. The caisson and working

shafts were then filled with concrete as well. On 17 May, the foundations were complete, and

erection of the Strauss bascule bridge superstructure began.[46

]

Workers

removed soil from within the caisson, allowing it to gradually descend until it came to rest at

50'-10" below the river's surface on 21 February 1908. At that point, a concrete mat was poured

to seal the floor of the caisson, and work on the cylindrical shafts began. The first shaft reached

bedrock on 9 March, and all had been filled with concrete by 3 April. The caisson and working

shafts were then filled with concrete as well. On 17 May, the foundations were complete, and

erection of the Strauss bascule bridge superstructure began.[46![]() ]

]

"Chiefly a Human Dynamo"

Biographies of Joseph Baermann Strauss focus on his five-foot height, as if a need to

compensate for it motivated his mechanical ingenuity, ceaseless invention, and political acumen.

On the fiftieth anniversary of San Francisco's Golden Gate Bridge, one publication directly

linked his ineligibility for the University of Cincinnati football team to his desire "to build the

biggest thing of its kind that a man could build."[47![]() ]

But Strauss' success stems from his keen

understanding of the kinematics of complex moving structures. About 150 patents, from window

sashes to prison doors, and amusement rides to airplanes, attest to his obsession with movement

and balance. Some of Strauss' patents cover the use of concrete in structures and vehicles,

showing a facility with that material as well. These two interests came together in Strauss' work

with bascule bridges, which started in Chicago and spread throughout the world.[48

]

But Strauss' success stems from his keen

understanding of the kinematics of complex moving structures. About 150 patents, from window

sashes to prison doors, and amusement rides to airplanes, attest to his obsession with movement

and balance. Some of Strauss' patents cover the use of concrete in structures and vehicles,

showing a facility with that material as well. These two interests came together in Strauss' work

with bascule bridges, which started in Chicago and spread throughout the world.[48![]() ]

]

Born in Cincinnati on 7 January 1870, Joseph B. Strauss belonged to a talented family of

musicians and artists. "In spite of his natural artistic and literary learnings," wrote one

biographer, "Mr. Strauss early showed a strong bent for mechanics and the sciences."[49![]() ]

Although

this flattering quote appeared in a company brochure, there could be some truth to the author's

assertion that Strauss' youth was spent observing mechanics and engineers at work. Strauss

proceeded through public schools to the University of Cincinnati, where he took part in student

activities both technical and literary. His years as Class President indicate an ego suited to

politics; as Class Poet, a confidence in written and verbal expression. After presenting a thesis

on bridging the Bering Strait, he received a civil engineering degree in 1892. These were the

makings of the Golden Gate Bridge's Chief Engineer, a role which Strauss played as more of a

promoter than a designer.[50

]

Although

this flattering quote appeared in a company brochure, there could be some truth to the author's

assertion that Strauss' youth was spent observing mechanics and engineers at work. Strauss

proceeded through public schools to the University of Cincinnati, where he took part in student

activities both technical and literary. His years as Class President indicate an ego suited to

politics; as Class Poet, a confidence in written and verbal expression. After presenting a thesis

on bridging the Bering Strait, he received a civil engineering degree in 1892. These were the

makings of the Golden Gate Bridge's Chief Engineer, a role which Strauss played as more of a

promoter than a designer.[50![]() ]

]

Strauss' years between Cincinnati and San Francisco are of greater concern to this report.

After graduating from college, he worked for two years with the New Jersey Bridge & Iron

Company in Trenton, then returned to teach for one year at his alma mater. He must have arrived

in Chicago with his new bride, college sweetheart May Van, around 1895. Employment at

Lassig Bridge & Iron Works, then at the Chicago Sanitary District, led to work on movable

bridges at Ralph Modjeski's engineering firm in 1899. According to engineering historian Henry

Petroski, Strauss left because his ideas about concrete counterweights and trunnion bearings

gained little acceptance there.[51![]() ]

]

Petroski implied that Strauss went directly to independent practice in 1902, but the

Western Society of Engineers' member directories tell a different story. Strauss became a

member of the society on 8 December 1899, and is listed as "Bridge Engineer, Monadnock

Block" in its 1900 and 1901 directories. If he was then with Modjeski's firm, it seems odd that

his employer's name was not mentioned. The next year, the listing changes to "Chief Engineer,

Hall Bascule Bridge Co., 97 Washington St."[52![]() ]

Departure from this firm, not Modjeski's, must

be the basis for the 1902 date in Petroski's book, which also appears in Strauss company

brochures. Strauss is listed as "Consulting Engineer, Opera House Block" in the 1903, 1904, and

1905 directories; the next year's issue contains the first mention of Strauss Bascule & Concrete

Bridge Company (incorporated 1904). According to one company brochure, Strauss

subsequently dropped "Concrete" from the name to reflect a focus on bascule spans. This

occurred in 1910 or 1911, after the Kinzie Street Bridge was constructed.[53

]

Departure from this firm, not Modjeski's, must

be the basis for the 1902 date in Petroski's book, which also appears in Strauss company

brochures. Strauss is listed as "Consulting Engineer, Opera House Block" in the 1903, 1904, and

1905 directories; the next year's issue contains the first mention of Strauss Bascule & Concrete

Bridge Company (incorporated 1904). According to one company brochure, Strauss

subsequently dropped "Concrete" from the name to reflect a focus on bascule spans. This

occurred in 1910 or 1911, after the Kinzie Street Bridge was constructed.[53![]() ]

By that time, Strauss'

bascule bridge designs had earned six U.S. patents and attention in the national engineering

press.

]

By that time, Strauss'

bascule bridge designs had earned six U.S. patents and attention in the national engineering

press.

Strauss' engineering firm achieved financial success with a strong belief in intellectual

property, reinforced by patents and defended by patent-infringement suits. Although bridge

engineers had sought exclusive rights to their designs as early as 1841, when Squire Whipple was

granted U.S. Patent No. 2,064 for "Construction of Iron-Truss Bridges," Strauss took it to new

extremes. A Strauss Bascule Bridge Company brochure produced circa 1925 devoted three

pages to the subject of patents, including a portrait of Donald M. Carter, the company's patent

attorney.[54![]() ]

Strauss' most well-known patent-infringement lawsuits were against the city of

Chicago in 1913 and against Seattle in 1921. Strauss claimed that both cities had constructed

bascule bridges with trunnion supports similar to his U.S. Patent No. 995,813, without paying

royalties for using the design. The courts decided against Chicago, and Seattle settled out of

court.[55

]

Strauss' most well-known patent-infringement lawsuits were against the city of

Chicago in 1913 and against Seattle in 1921. Strauss claimed that both cities had constructed

bascule bridges with trunnion supports similar to his U.S. Patent No. 995,813, without paying

royalties for using the design. The courts decided against Chicago, and Seattle settled out of

court.[55![]() ]

As the defensive tone of Strauss' brochure might indicate, the lawsuits earned him

criticism from some fellow engineers, while others would have agreed with his desire to recoup

the expense of a long-term effort to improve the bascule bridge.

]

As the defensive tone of Strauss' brochure might indicate, the lawsuits earned him

criticism from some fellow engineers, while others would have agreed with his desire to recoup

the expense of a long-term effort to improve the bascule bridge.

The engineering profession's debate over proprietary designs neither began nor ended

with Strauss' bascule bridges. As early as 1902, discussions in the American Society of Civil

Engineers' Transactions pitted pro-patent engineers against those who felt that the existence of

proprietary designs "lowers the dignity of the profession."[56![]() ]

Citing the medical profession's

ethical restriction on patenting medical instruments, opponents claimed that engineering patents

impeded progress toward public good. Another important point of dispute was whether

engineers made unfair gains by charging royalties for proprietary designs. A powerful counter-argument, in the words of engineer S. Whinery, was that engineers "must have some assurance

that, after they have spent large sums for the development and introduction of the invention, they

will be able to prevent competitors from robbing them of the reward."[57

]

Citing the medical profession's

ethical restriction on patenting medical instruments, opponents claimed that engineering patents

impeded progress toward public good. Another important point of dispute was whether

engineers made unfair gains by charging royalties for proprietary designs. A powerful counter-argument, in the words of engineer S. Whinery, was that engineers "must have some assurance

that, after they have spent large sums for the development and introduction of the invention, they

will be able to prevent competitors from robbing them of the reward."[57![]() ]

Undoubtedly, Strauss'

continual improvement of the bascule bridge was financed by the dozens of clients who chose to

pay for his proprietary design. As stated in Strauss' brochure, clients chose patented designs in

an open market, therefore "the only hope for a patented product lies in its ability to do things at

less cost or to do them better."[58

]

Undoubtedly, Strauss'

continual improvement of the bascule bridge was financed by the dozens of clients who chose to

pay for his proprietary design. As stated in Strauss' brochure, clients chose patented designs in

an open market, therefore "the only hope for a patented product lies in its ability to do things at

less cost or to do them better."[58![]() ]

]

The Evolving Strauss Bascule Bridge

Although the Kinzie Street Bridge is an early example of a Strauss bascule span, it either

includes or foreshadows many of the features found in the mature design. The engineer himself

recognized that the Kinzie Street Bridge represented an important developmental step on the way

to the heel-trunnion bascule that became his most recognizable movable bridge design. In

Strauss' 1925 brochure, a photograph of the Kinzie Street Bridge is identified as the "Second

Step in Strauss Bascule Bridges."[59![]() ]

]

Before describing the process of development, however, a basic identification of design

issues is necessary. A bascule bridge is defined by a movable span, or leaf, rotating about a

horizontal axis. Usually the work of rotation is made easier by balancing the leaf with a

counterweight on the other side of the axis. The axis can be either stationary, where the leaf

rotates about a fixed trunnion, or moving, where the leaf rocks or rolls along a track. Almost all

of Strauss' bascule bridges have fixed trunnions, where the structure's weight is always delivered

to the foundation at the same point. Strauss was granted a patent for an electromagnet-driven

rolling bascule bridge in 1908, but no such spans were ever constructed.[60![]() ]

For the most part,

Strauss recognized and avoided the troublesome situation of a rolling leaf imposing a moving

load on its foundation. Another major variable in bascule bridge design is the connection

between the leaf and its counterweight. If rigidly attached, the counterweight must descend

while the leaf ascends, requiring a pit below the roadway level. To reduce the pit's depth, the

counterweight arm can be made shorter, but then the counterweight must be proportionately

heavier. This is because balance is dictated by not only weight, but also the distance at which the

weight is located from the axis of rotation. As an alternative to rigid attachment, the

counterweight could be connected to the leaf by mechanical links and kept above the roadway

level. Without the restrictions of a pit, the counterweight could be made any size, a significant

improvement because concrete is significantly less expensive—but significantly less dense—than steel or pig iron.

]

For the most part,

Strauss recognized and avoided the troublesome situation of a rolling leaf imposing a moving

load on its foundation. Another major variable in bascule bridge design is the connection

between the leaf and its counterweight. If rigidly attached, the counterweight must descend

while the leaf ascends, requiring a pit below the roadway level. To reduce the pit's depth, the

counterweight arm can be made shorter, but then the counterweight must be proportionately

heavier. This is because balance is dictated by not only weight, but also the distance at which the

weight is located from the axis of rotation. As an alternative to rigid attachment, the

counterweight could be connected to the leaf by mechanical links and kept above the roadway

level. Without the restrictions of a pit, the counterweight could be made any size, a significant

improvement because concrete is significantly less expensive—but significantly less dense—than steel or pig iron.

The idea of a separate counterweight did not originate with Strauss, but he did make

significant advances in the design of mechanical links, both before and after the Kinzie Street

Bridge. In essays on the history of bascule bridges, Strauss and his contemporaries listed

numerous means of ensuring that the counterweight balanced the leaf throughout its range of

motion. These included weights rolling down sinusoidally curved tracks, suspended from ropes

wound around spiral drums, or divided into segments and dropped in sequence.[61![]() ]

Strauss' early

schemes were no less inventive. In 1901, he patented a bascule bridge with counterweights that

descended in the river as the span opened, so their downward pull was reduced by buoyant

force.[62

]

Strauss' early

schemes were no less inventive. In 1901, he patented a bascule bridge with counterweights that

descended in the river as the span opened, so their downward pull was reduced by buoyant

force.[62![]() ]

This impractical design was never built, but he soon hit upon the parallel-link concept

that made him famous. Strauss freely acknowledged a basic similarity between his bascule

designs and nineteenth-century Dutch bridges, both of which included a parallelogram-shaped

configuration of links.[63

]

This impractical design was never built, but he soon hit upon the parallel-link concept

that made him famous. Strauss freely acknowledged a basic similarity between his bascule

designs and nineteenth-century Dutch bridges, both of which included a parallelogram-shaped

configuration of links.[63![]() ]

He claimed originality, however, in configuring the movable truss and

the trunnion supports so that the counterweight could occupy most of the span's width and yet

pass beneath the trunnions during rotation. This arrangement permitted a large (i.e., concrete)

counterweight with a minimum of pit excavation. Although Strauss' infringement suits were

based on a 1911 patent, this same feature also appears in a patent issued eight years earlier.

]

He claimed originality, however, in configuring the movable truss and

the trunnion supports so that the counterweight could occupy most of the span's width and yet

pass beneath the trunnions during rotation. This arrangement permitted a large (i.e., concrete)

counterweight with a minimum of pit excavation. Although Strauss' infringement suits were

based on a 1911 patent, this same feature also appears in a patent issued eight years earlier.

As with many design patents, the text of U.S. Patent No. 738,954 makes vague claims

with the hope of protecting the widest possible range of designs. The drawings, of bascule leaves

with counterweights below deck, do not even show the classic Strauss parallelogram of

counterweight links. The configuration is more accurately described as a quadrilateral that

collapses into a triangle when the bridge is fully open.[64![]() ]

Even so, the links force the

counterweight to remain vertical, using the full effect of its weight to balance the leaf in any

position. By the time that Strauss had constructed his first bascule bridge for the Wheeling &

Lake Erie Railroad (W&LE) in Cleveland, he had adopted the parallel arrangement of links to

support an overhead counterweight. Demonstrating the flexibility of his patent's claims, Strauss

implied that it protected the W&LE bridge. "Although thus first applied in the overhead type of

bridge in 1904," he wrote, "the pin-connected concrete counterweight was originally proposed by

the writer for the underneath counterweight type of bascule in 1901 in a series of plans ... later

embodied in patent application No. 738,954."[65

]

Even so, the links force the

counterweight to remain vertical, using the full effect of its weight to balance the leaf in any

position. By the time that Strauss had constructed his first bascule bridge for the Wheeling &

Lake Erie Railroad (W&LE) in Cleveland, he had adopted the parallel arrangement of links to

support an overhead counterweight. Demonstrating the flexibility of his patent's claims, Strauss

implied that it protected the W&LE bridge. "Although thus first applied in the overhead type of

bridge in 1904," he wrote, "the pin-connected concrete counterweight was originally proposed by

the writer for the underneath counterweight type of bascule in 1901 in a series of plans ... later

embodied in patent application No. 738,954."[65![]() ]

The Kinzie Street Bridge's design can also be

considered as a descendant of this patent, even though the trunnion sits above the leaf rather than

below it. Interestingly, the C&NW's application for a War Department permit shows a bascule

span remarkably similar to Patent No. 738,954, even though the Kinzie Street Bridge turned out

much different in form.[66

]

The Kinzie Street Bridge's design can also be

considered as a descendant of this patent, even though the trunnion sits above the leaf rather than

below it. Interestingly, the C&NW's application for a War Department permit shows a bascule

span remarkably similar to Patent No. 738,954, even though the Kinzie Street Bridge turned out

much different in form.[66![]() ]

Strauss applied for a patent to protect the overhead-trunnion version of

his design in March 1908, but it was not issued until August 1915.[67

]

Strauss applied for a patent to protect the overhead-trunnion version of

his design in March 1908, but it was not issued until August 1915.[67![]() ]

By that time, the Strauss

bascule bridge had evolved once more to the heel-trunnion type.

]

By that time, the Strauss

bascule bridge had evolved once more to the heel-trunnion type.

|

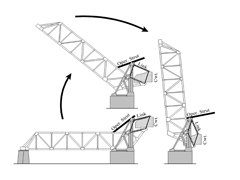

| Figure 1. Schematic of Kinzie Street Bridge (not to scale), with stationary parts in grey tone. Sketch by author. |

As the "Second Step in Strauss Bascule Bridges," the Kinzie Street Bridge improved upon the W&LE bridge's shortcomings, and anticipated the mature (i.e., heel-trunnion) Strauss bascule form. Figure 1 shows the Kinzie Street Bridge in three positions: closed, open halfway, and at its maximum inclination of 85 degrees to the horizontal.

As shown in the figure, the structure consists of three main parts, a fixed tower, a rotating bascule leaf, and a concrete counterweight rotating independently from the leaf. The leaf's axis of rotation, the main trunnion, is located about halfway up the tower. Note that the main trunnion is located in the truss' upper chord. Extending through the tower, the truss has an inclined rear arm to support the counterweight. Parallel to this, a link beam connects the top of the counterweight to the tower. These two elements remain parallel throughout the span's rotation, as is shown by the bold parallelogram. As the span reaches its fully open position, the counterweight passes between the rear arms of the truss, a compact arrangement that does not require a tail pit. To prevent the span from opening further than 85 degrees, the rear arms of the truss engage a wooden bumper on the tower. Motive power is provided by a pinion at the top of the tower, which engages a rack on the operating strut to raise or lower the leaf.

The Kinzie Street Bridge differs from the W&LE bridge in three major aspects. Most noticeably, Strauss moved the main trunnion from the lower chord to the upper chord. This allowed the leaf to support the counterweight directly in the Kinzie Street Bridge, simplifying the system of links and making the parallelogram more compact. Another result was the change from a rectangular tower on the W&LE bridge to a more efficient triangular one on the Kinzie Street and subsequent bridges. The third and most subtle change was the provision of a separate support for the Kinzie Street Bridge's main trunnion. Looking carefully at Figure 1, one notices that the tower's vertical leg actually consists of two members, one supporting the operating machinery and counterweight link trunnion, the other supporting the main trunnion. The W&LE bridge's main trunnion, in contrast, was supported by girders spanning between the front legs of the tower. This change made little difference in the operation of the bridge, but it does signify that Strauss was beginning to recognize the inefficiency of concentrating the entire load of leaf and counterweight at a single point.

After the Kinzie Street Bridge, the next step in the evolution of Strauss bascule bridges

was to separate the leaf and counterweight loads to opposite sides of the tower. Strauss also

moved the leaf out in front of the tower, with the end of its lower chord pivoting on a main

trunnion which sat directly on the foundation. In the analogy of a tapping foot, the trunnion

occurs at the heel, so this new form was called a heel-trunnion bascule bridge. This helped to

remedy a deficiency shared by the W&LE and Kinzie Street bridges: their leaf and tower trusses

did not lie in the same plane.[68![]() ]

Because the leaf truss had to pass through the tower, it was offset

from the tower trusses on either side, subjecting the trunnions to a high shearing force. With the

trusses co-planar and the counterweight load supported elsewhere, the heel-trunnion bascule

bridge required main trunnions proportionately smaller than its predecessors. Although the

Kinzie Street Bridge had the world's longest and heaviest bascule leaf at the time of its

construction, Strauss' heel-trunnion design shattered the record again and again.[69

]

Because the leaf truss had to pass through the tower, it was offset

from the tower trusses on either side, subjecting the trunnions to a high shearing force. With the

trusses co-planar and the counterweight load supported elsewhere, the heel-trunnion bascule

bridge required main trunnions proportionately smaller than its predecessors. Although the

Kinzie Street Bridge had the world's longest and heaviest bascule leaf at the time of its

construction, Strauss' heel-trunnion design shattered the record again and again.[69![]() ]

As Strauss'

brochure confirmed, the Kinzie Street Bridge was an important step along the way.

]

As Strauss'

brochure confirmed, the Kinzie Street Bridge was an important step along the way.

Design and Construction: Superstructure

One additional advantage of the Strauss bascule form was that it could be erected in an upright position, with a minimum of interference to traffic on the river below. This worked particularly well on the cramped Kinzie Street site, where the existing swing bridge had to continue operating throughout the construction sequence. The majority of erection work therefore took place on the river's east bank, where contractors had to work around the C&NW's busy Wells Street Station yard.

The low bidders on the Kinzie Street Bridge superstructure were names that appeared

time and again throughout the flurry of bridge replacements in Chicago during the first decades

of the twentieth century. The erection contract went to the Kelly-Atkinson Company, which, like

Great Lakes Dredge & Dock, also maintained headquarters in Chicago. The pair worked

together on Strauss heel trunnion bridges elsewhere, for the Chicago & Western Indiana Railroad

over the Calumet River in 1912, and for the C&NW over the North Branch at Deering in 1916.[70![]() ]

Despite its distant fabricating plant, the Toledo-Massillon Bridge Company of Toledo, Ohio, was

not unfamiliar with Chicago's rivers, having fabricated bridges in the city since at least 1881.[71

]

Despite its distant fabricating plant, the Toledo-Massillon Bridge Company of Toledo, Ohio, was

not unfamiliar with Chicago's rivers, having fabricated bridges in the city since at least 1881.[71![]() ]

]

|

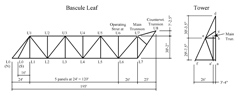

| Figure 2. South elevation of Kinzie Street Bridge leaf and tower trusses (not to scale). Sketch by author. |

The Kinzie Street Bridge's bascule leaf weighs about 800 tons and consists of two

Warren through trusses with verticals, of unequal length, spaced 29'-10" on center.[72![]() ]

As shown

in Figure 2, both trusses measure 30'-2" deep between center-lines of their upper and lower

chords. Lateral bracing in the upper and lower planes forms an "X" in each panel, except U7-U8,

where it would interfere with the counterweight. Proceeding west from the main trunnion at U7,

the north truss has one panel 26'-0" long followed by six panels each 24'-0" long, for a total of

170'-0", the dimension usually cited as the bridge's length. The south truss, however, has one

panel 26'-0" long, then five panels 24'-0" long, with the seventh panel of 16'-0" resulting in a 15-degree skew on the west end. Clipping the last panel of the south truss may represent an effort to

reduce span weight rather than a true accommodation of the crossing's skew alignment. Given

that the axis of rotation must be perpendicular to the bridge's axis, bascule bridges cannot be

skewed more than a few degrees. (Note that the Kinzie Street Bridge's east end is square.)

Although an asymmetrical distribution of weight between the trusses produces uneven loads on

the trunnions when the span is open, Strauss must have considered the difference minor

compared to the overall reduction in weight.[73

]

As shown

in Figure 2, both trusses measure 30'-2" deep between center-lines of their upper and lower

chords. Lateral bracing in the upper and lower planes forms an "X" in each panel, except U7-U8,

where it would interfere with the counterweight. Proceeding west from the main trunnion at U7,

the north truss has one panel 26'-0" long followed by six panels each 24'-0" long, for a total of

170'-0", the dimension usually cited as the bridge's length. The south truss, however, has one

panel 26'-0" long, then five panels 24'-0" long, with the seventh panel of 16'-0" resulting in a 15-degree skew on the west end. Clipping the last panel of the south truss may represent an effort to

reduce span weight rather than a true accommodation of the crossing's skew alignment. Given

that the axis of rotation must be perpendicular to the bridge's axis, bascule bridges cannot be

skewed more than a few degrees. (Note that the Kinzie Street Bridge's east end is square.)

Although an asymmetrical distribution of weight between the trusses produces uneven loads on

the trunnions when the span is open, Strauss must have considered the difference minor

compared to the overall reduction in weight.[73![]() ]

Typical of early twentieth-century truss

construction, all steel members in the Kinzie Street Bridge are built up from rolled sections such

as angles, channels, lacing, and plates. All connections are riveted together with gusset plates,

with particularly heavy reinforcement around the rotating joints.

]

Typical of early twentieth-century truss

construction, all steel members in the Kinzie Street Bridge are built up from rolled sections such

as angles, channels, lacing, and plates. All connections are riveted together with gusset plates,

with particularly heavy reinforcement around the rotating joints.

The leaf rotates about 23-3/4"-diameter main trunnions at U7, which are supported on

separate posts offset 3'-4" from the tower's rear legs. These posts were filled with concrete to

increase their strength.[74![]() ]

Each truss' top chord extends 25'-0" beyond the main trunnion, rising

7'-2-1/2" to meet a 12"-diameter counterweight pin at U8. A counterweight link, not shown in

Figure 2, is parallel to member U7-U8 and keeps the counterweight in a vertical position. The

link is attached to the tower just below point "d," and to the top of the counterweight, with 7"-diameter pins at each location. The counterweight itself weighs about 1,247 tons and is concrete

reinforced with old rails, on a structural steel frame. Truss member U7-U8, counterweight, link,

and tower form the parallelogram characteristic of Strauss' bascule bridge designs.

]

Each truss' top chord extends 25'-0" beyond the main trunnion, rising

7'-2-1/2" to meet a 12"-diameter counterweight pin at U8. A counterweight link, not shown in

Figure 2, is parallel to member U7-U8 and keeps the counterweight in a vertical position. The

link is attached to the tower just below point "d," and to the top of the counterweight, with 7"-diameter pins at each location. The counterweight itself weighs about 1,247 tons and is concrete

reinforced with old rails, on a structural steel frame. Truss member U7-U8, counterweight, link,

and tower form the parallelogram characteristic of Strauss' bascule bridge designs.

Attesting to the near-perfect balance between leaf and counterweight, relatively little

power is needed to operate the span. This was originally supplied by two 50-horsepower direct-current electric motors located in a reinforced concrete machinery house at the top of the tower.

(Repair records do not indicate whether these were later replaced with alternating-current

equipment.[75![]() ]) Through a series of reduction gears, the motors turn the two pinions that engage

racks on the operating struts attached to the leaf at panel point U6. To lift the span, the motors

need only overcome friction in the trunnions, plus the additional weight of water, dirt, or snow

that might have accumulated on the span. Each pinion is kept in contact with the rack by a

triangular harness that rolls along the top flange of the operating strut, pulling the pinion against

the rack on the bottom flange. A "spur gear equalizer," or differential, distributes torque between

the two motors and the two pinions so that they turn at equal rates. According to an article in

Iron Age, the Kinzie Street Bridge had not only two sources of electrical power in its original

configuration, but also "an air motor" and provision for manual operation. An equal number of

braking mechanisms were provided: a solenoid brake on each motor, a hand brake, and a brake

automatically engaged by limit switches as the bridge approached its fully open or closed

position.[76

]) Through a series of reduction gears, the motors turn the two pinions that engage

racks on the operating struts attached to the leaf at panel point U6. To lift the span, the motors

need only overcome friction in the trunnions, plus the additional weight of water, dirt, or snow

that might have accumulated on the span. Each pinion is kept in contact with the rack by a

triangular harness that rolls along the top flange of the operating strut, pulling the pinion against

the rack on the bottom flange. A "spur gear equalizer," or differential, distributes torque between

the two motors and the two pinions so that they turn at equal rates. According to an article in

Iron Age, the Kinzie Street Bridge had not only two sources of electrical power in its original

configuration, but also "an air motor" and provision for manual operation. An equal number of

braking mechanisms were provided: a solenoid brake on each motor, a hand brake, and a brake

automatically engaged by limit switches as the bridge approached its fully open or closed

position.[76![]() ]

Except for the solenoid brakes, the braking mechanisms act on the drive train.

Braking the drive train was not particularly safe and risked burning out the motors, so Strauss

subsequently devised brakes that acted on the operating struts.[77

]

Except for the solenoid brakes, the braking mechanisms act on the drive train.

Braking the drive train was not particularly safe and risked burning out the motors, so Strauss

subsequently devised brakes that acted on the operating struts.[77![]() ]

]

The machinery is controlled from an operator's house, which is cantilevered out from the

north side of the tower above point "e" in Figure 2. Like the machinery house above point "f,"

the operator's house is constructed of reinforced concrete panels in a steel frame. This is a

significant feature found on few Strauss bascule bridges. Even the C&NW's bridge at Deering

Station, a Strauss heel-trunnion bascule completed in 1916, has a steel frame with wood infill.[78![]() ]

In addition to the drive machinery and brakes, the bridge operator must also control two locking

mechanisms. The first is a wedge driven to latch the tip of the leaf (panel point L0) down to the

rest pier. Because the leaf is almost perfectly balanced, this is a necessary precaution against it

rising off the rest pier while a train is on the span. A second wedge beneath panel point L7,

which Strauss' drawings call the "front support," transmits the weight of passing trains directly to

the abutment.[79

]

In addition to the drive machinery and brakes, the bridge operator must also control two locking

mechanisms. The first is a wedge driven to latch the tip of the leaf (panel point L0) down to the

rest pier. Because the leaf is almost perfectly balanced, this is a necessary precaution against it